Wataynikaneyap Power Project: First Nations Controlling Development on their Land

February 21, 2024

The Wataynikaneyap Power Project was presented as part of EDIST 2024. The project connects 17 First Nations to the provincial power grid, capital cost is estimated at $1.9 billion. The ownership model is unprecedented with First Nations controlling development on their land, owned by 24 First Nations in partnership with Fortis Inc, as well as other private investors. The First Nations also maintain ability to increase their ownership and control to 100% 25-years after in service operation date.

Eleven of the 17 First Nations have been energized up to date. The remaining eight stations will be energized by the end of June 2024.

Presenters

Ken Kopechanski – Sr. Electrical Engineer with Wataynikaneyap Power

Armando Simeoni – Asset Management Lead with Wataynikaneyap Power

Aleks Modelewska – Director, Business Development with Engineered Intelligence

Project Overview

Objective:

Bring reliable and sustainable electricity to remote First Nations in Northwestern Ontario that currently rely on diesel generators.

Remote location challenges:

Geographical: harsh weather, rugged terrains; Logistical: transporting equipment, materials, and personnel remote locations; Environmental: minimize ecological disruptions.

System Overview:

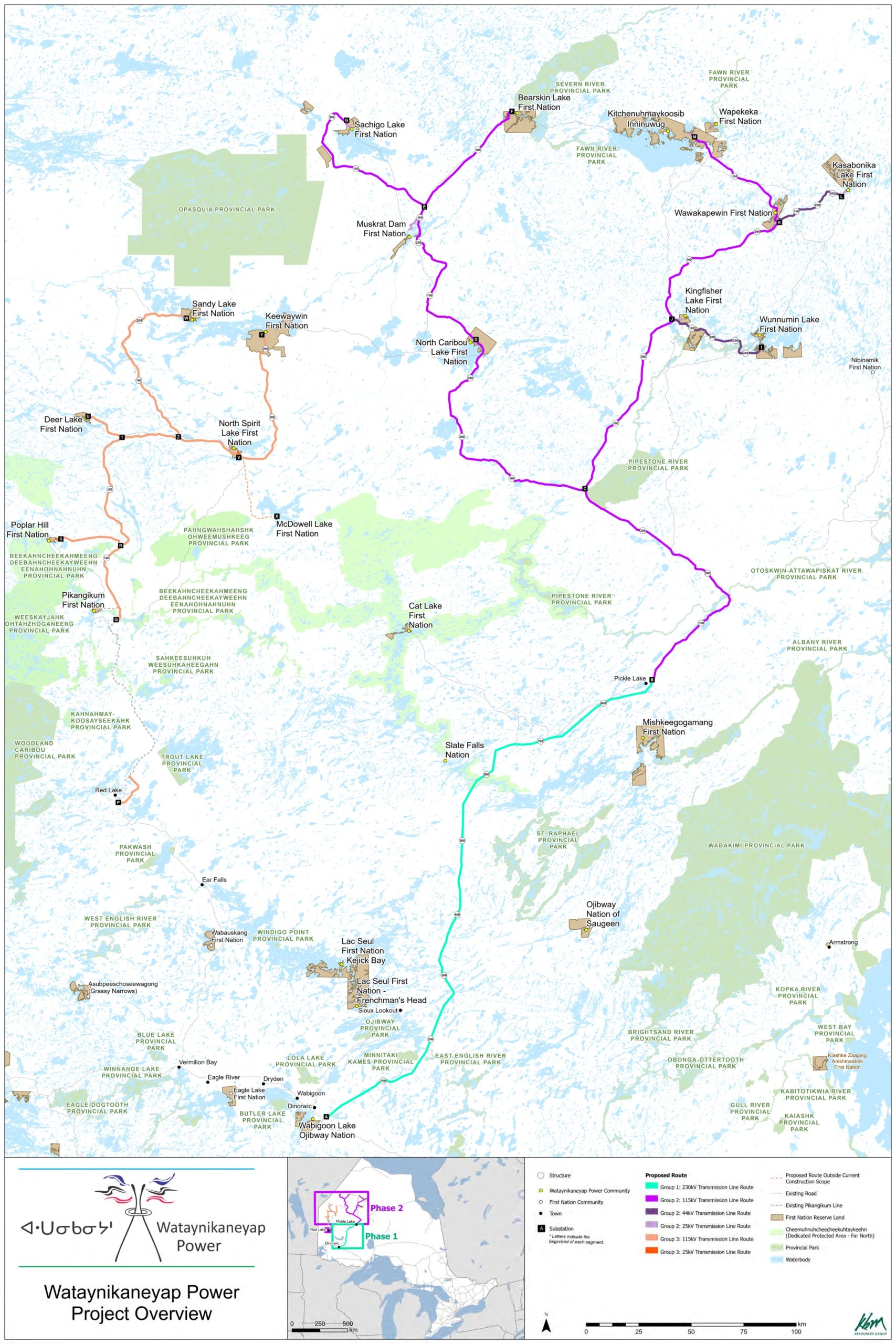

Approximately 1,800 km of 230kV, 115k 44kV, and 25 kV transmission line; Combination of steel and wood pole structures; 23 associated TS’s and SS’s, with a total of 31 power transformers, 19 variable and fixed shunt reactors, 95 HV breakers and circuit switchers, with associated relay protections, telecom infrastructure, SCADA resources and building infrastructure.

Preliminary phase: (dotted line from P to Q) in 2018, Pikangikum First Nation was first connected at 44 kV from Red Lake via Hydro One.

Phase 1: (green line) to reinforce the existing system.

Phase 2: (purple and tan lines) to connect First Nations north of Pickle Lake and Red Lake.

Economic Benefits

Part of the sustainability and long-term viability of this project relies on engagement and employment opportunities for nearby residents. Having people in the communities working for Watay Power reduces response time and limits the need for personnel transportation and the geographic challenges associated with that.

Reducing the reliance of remote communities on diesel generators is a key aspect of the project, as well. Along with providing a more sustainable, environmentally friendly energy source, it also reduces the economic burden associated with diesel fuel transportation to remote locations.

“With a reliable source of electricity, these communities can now support and enjoy the same infrastructure development as other grid connected communities,” Kopechanski said. “Of course, with that there’s also other economic development opportunities to improve the employment prospects for people in these communities.”

Diesel generation has associated health risks, it is increasingly expensive, and difficult to transport to remote locations, it is also not easily expandable – meaning communities operate near their maximum power capacity, which results in load restrictions and several power outages. This is a major barrier to economic development in these First Nations communities.

Wataynikaneyap Power Guiding Principles

“Our people expect that the Wataynikaneyap Power Project will be undertaken in a manner that respects our lands, rights, and principles; our way of life on the land and as part of the land; and our land sharing protocols.”

- The Project shall not poison the lands;

- No herbicides shall be used throughout the life of the transmission line to control vegetation;

- The Project shall be constructed, operated and maintained in a manner that observes and does not interfere with seasonal hunting, trapping, fishing and harvesting and keeps disturbances to a minimum;

- No new transmission lines shall be located underwater; and

- The Project will develop and implement an environmental and social management plan which will include acceptable and effective mitigation measures for any sacred sites, gathering sites, and harvesting sites

Long-Term Viability

The project’s planning involves considerations for the long-term viability of the transmission system. This includes maintenance strategies, technology upgrades, and adapting to changing needs in the region.

Infrastructure is in its early service life: establishing robust asset management processes becomes paramount for condition monitoring to identify priority work. The asset management strategy includes a comprehensive approach to monitoring, maintaining, and optimizing power infrastructure and utilizing technology.

After an RFP process, Watay Power selected ENGIN by Engineered Intelligence Inc. for condition monitoring and asset management.

The remote location of the transmission lines makes it difficult to respond in person for service and troubleshooting, which makes maintenance a critical focus. To make the project viable, maintenance must be focused as well as bundled together, anomalies need to be identified, prioritized, and addressed appropriately. Getting there with tools and equipment is a challenge, so return trips must be minimized.

The closest station of the transmission line is 300 KMs from Watay Power’s office in Thunder Bay and most of their stations are not road accessible.

Armando Simeoni, Asset Management Lead with Watay Power explained:

“With our equipment being brand new, currently there’s not much need for investment funds. However, we have all our in-service data and commissioning records readily available to compare with upcoming inspection findings, as well as any equipment malfunctions or failures. In addition to this, we are conducting quarterly inspections on all of our stations as they are energized. We are currently also developing a full inspection and maintenance plan, bearing in mind that time-based maintenance activities can be costly and very inefficient. Therefore, this drives the need for a condition-based maintenance strategy that continuously monitors, ensures asset conditions to decide when maintenance needs to be done.

Knowing that the resulting data and information needs to be retrieved, sorted and analyzed to identify and prioritize our maintenance needs, we decided to partner with Engineered Intelligence to implement their asset management condition monitoring solution ENGIN.”

Software Implementation Process

Phase 1: They are currently working on implementing core modules:

- Analyzer, Optimizer,

- Forecaster,

- LIVE for SF6 Breakers,

- CMMS Lite – Asset Registry

Phase 2 will include the Mobile Application and Inspection App.

Aleks Modelewska, Director, Business Development with Engineered Intelligence spoke to the condition monitoring solution provided by Engineered Intelligence.

Modelewska noted Engineered Intelligence expected to encounter hurdles throughout the implementation process, as is typically the case, however, given the unique aspects of the Watay Power project, the software implementation has been a smooth process.

The core features Engineered Intelligence provides utilities are their analyzer, optimizer, and forecaster. Along with those features, Watay Power also opted for LIVE for SF6 Breakers, CMMS Lite Asset Registry, and ENGIN Mobile.

“Upon completion of implementation, Watay Power will be able to have their automated asset health indices of every single one of their assets. They will have risk scores and risk analyses of all of their assets readily at their fingertips, they will be able to optimize their investment planning and will be provided with 10-year plans that they can tweak and play around with as they see fit. These investment plans will be based on lowering risk across the entire system and making sure that the best investments are made in a timely manner, in the future,” she explained.

“They will be able to forecast their reliability predictions using our forecaster and they will be able to view all of this on our geospatial viewer on an interactive map where they will be able to create projects in the future based on all of those calculations and risk-based analysis from the other applications or the other model.”

The live module will provide them with their failure mode monitoring and allow them to have any alarms at their fingertips on their phones. They will be able to have all of their inventory stored With the CMMS Lite, all the data will be able to be collected directly from the field using the inspection app.

They are currently in the middle/closer the beginning of the implementation process. At the end of April their team will be heading to the Watay Power office in Thunder Bay to conduct initial testing for the ENGIN Mobile App.

With the ENGIN app they will be able to harness all the data they’re collecting. Currently, the majority of data is coming from their quarterly inspections, but they will also be collecting live data from their SCADA system.

“We’ll be able to use that (data analysis) to help provide a reliable predictive maintenance program and continuous asset monitoring,” noted Kopechanski.